Why Is the Washing Machine Motor Commutator So Important for Stable Performance?

2025-10-29

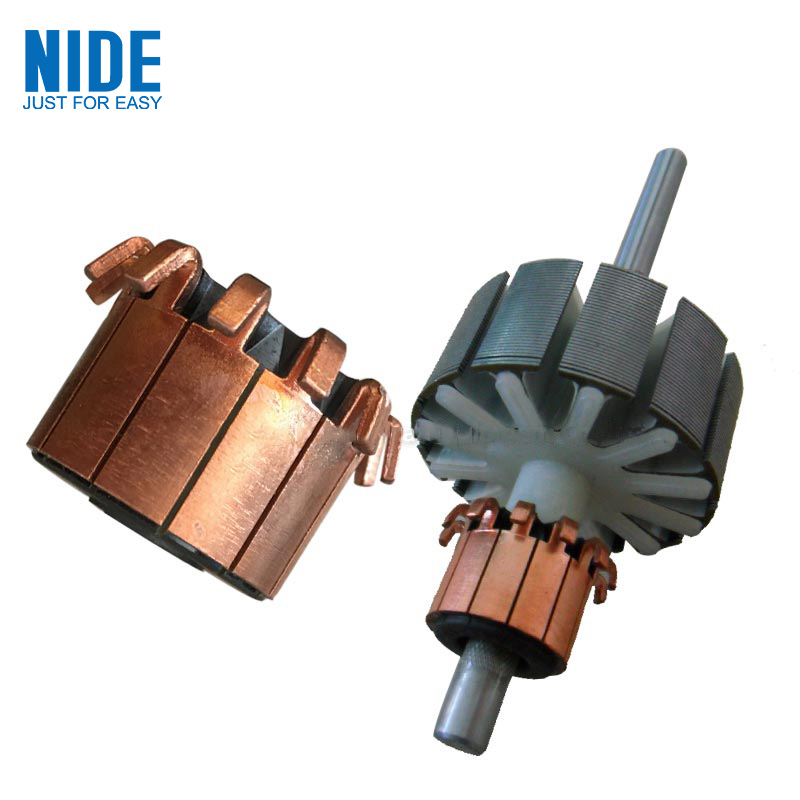

When it comes to maintaining the efficiency and durability of a washing machine, the Washing Machine Motor Commutator plays a critical role. As the essential component that connects the armature coil and ensures current direction switching, the commutator directly affects the rotation speed, torque, and overall performance of the motor. At Ningbo Haishu Nide International Co., Ltd., we specialize in producing high-quality motor commutators that meet international standards and are trusted by top appliance manufacturers worldwide.

What Is the Function of a Washing Machine Motor Commutator?

The Washing Machine Motor Commutator is a rotating electrical switch that periodically reverses the current direction between the rotor and the external circuit. It ensures that the armature winding receives consistent torque, allowing the motor to spin smoothly in the desired direction. Without a reliable commutator, the motor would fail to maintain stable speed and power output, leading to washing machine malfunctions.

In simpler terms, this small but crucial part makes sure that electrical energy is converted efficiently into mechanical motion. It guarantees your washing machine runs quietly, powerfully, and without vibration, even under high load conditions.

Main Features and Technical Parameters

| Item | Specification |

|---|---|

| Material | High-conductivity copper segments |

| Diameter Range | 8mm – 60mm |

| Application | Washing machine universal motor |

| Insulation Resistance | ≥ 100MΩ |

| Dynamic Balance | ≤ 0.5g |

| Surface Hardness | HV ≥ 180 |

| Temperature Resistance | Up to 180°C |

| Lifespan | > 2000 hours continuous operation |

All commutators produced by Ningbo Haishu Nide International Co., Ltd. go through strict quality inspections to ensure perfect concentricity, durability, and stable electrical conductivity.

How Does It Affect the Washing Machine's Performance?

A high-quality Washing Machine Motor Commutator directly enhances the efficiency of the entire motor system. When the commutator is made with precision copper segments and strong insulation materials, it minimizes spark generation, reduces wear, and extends the lifespan of the brushes and armature.

In my experience, when we upgraded to a more durable commutator, the motor performance improved noticeably—less noise, lower temperature rise, and smoother start-up. This is why every washing machine manufacturer values the quality of this component.

Why Choose Ningbo Haishu Nide International Co., Ltd.?

As one of the leading manufacturers in the motor component industry, Ningbo Haishu Nide International Co., Ltd. offers:

-

Comprehensive Design Solutions – Custom sizes and materials according to your motor specifications.

-

High Production Precision – Fully automated equipment ensures excellent concentricity and balance.

-

Strict Quality Control – Each commutator undergoes dynamic balancing, hardness testing, and conductivity verification.

-

Global Supply Capability – Exporting to Europe, America, and Southeast Asia for years.

When I first used Nide's commutators in a client's washing machine project, I saw the performance difference immediately—the motor's vibration level dropped significantly, proving the stability and quality of their products.

Q&A: Common Questions About Washing Machine Motor Commutator

Q1: What happens if the Washing Machine Motor Commutator is damaged?

A1: If the commutator is worn or burned, the washing machine may produce sparks, unusual noise, or fail to spin. Replacing it promptly with a high-quality commutator prevents further motor damage.

Q2: How often should the commutator be inspected or replaced?

A2: Under normal usage, it's advisable to inspect the commutator every 2–3 years. If there are signs of excessive wear or carbon buildup, replacement is recommended to maintain motor efficiency.

Q3: Why should I choose Ningbo Haishu Nide International Co., Ltd. for commutator supply?

A3: Because we combine advanced manufacturing technology, consistent quality, and customized service to ensure your washing machine motors perform optimally for years. Our commutators are designed for both performance and longevity, backed by years of export experience and trusted customer feedback.

The Importance of Quality in Motor Components

The commutator is not just a small accessory—it's the heart of the DC motor system. A precision-engineered Washing Machine Motor Commutator ensures smooth operation, lower maintenance costs, and better energy efficiency. At Nide, we understand that every detail matters. Our technical team continuously improves materials, insulation processes, and balance accuracy to deliver commutators that enhance your motor's overall performance.

As a manufacturer, I take pride in offering products that represent both technical strength and reliability. Every washing machine that uses our commutators reflects our commitment to quality and innovation.

Conclusion

Choosing a reliable Washing Machine Motor Commutator means choosing stability, efficiency, and longer service life for your washing machine motors. With advanced production technology and strict testing standards, Ningbo Haishu Nide International Co., Ltd. is your trusted partner for high-performance commutators and motor components.

If you're looking for professional solutions or customized designs, contact us today — we're ready to provide the best products and services tailored to your needs.