What Is The Lifespan Of A Precious Metal Brush Motor In Industrial Equipment

2025-10-30

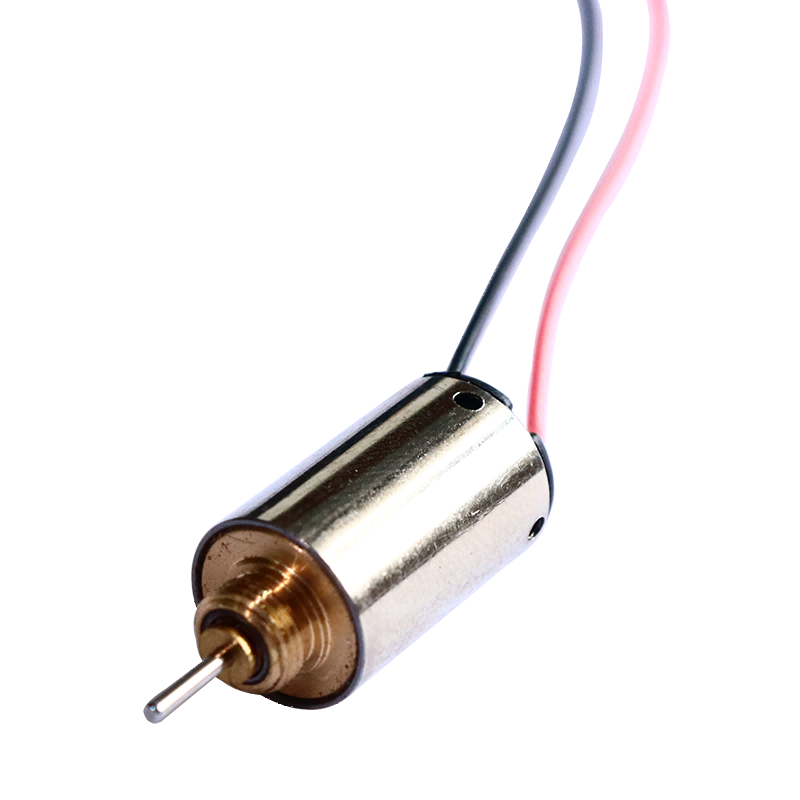

When evaluating motor options for industrial equipment, one critical question often arises: what is the actual lifespan of a Precious Metal Brush Motor? At Ruixing, we understand that downtime costs money, and selecting the right motor technology directly impacts your operational efficiency and maintenance schedules. Unlike standard carbon brush motors that typically last 300-500 hours, a well-engineered Precious Metal Brush Motor from Ruixing can deliver 1,000 to 2,000 hours of reliable service, even in demanding conditions.

What Key Factors Determine the Longevity of a Precious Metal Brush Motor

The extended service life of our motors is not accidental; it is the result of precision engineering and superior materials. The lifespan is primarily influenced by several key parameters that we optimize at Ruixing:

-

Brush Material: We use advanced silver-palladium alloys, which offer significantly lower electrical resistance and wear compared to carbon.

-

Commutator Surface Finish: A mirror-smooth commutator surface minimizes friction and brush wear.

-

Operating Voltage and Load: Consistent operation within the motor's designed specifications ensures optimal performance.

-

Environmental Conditions: Protection from excessive dust, moisture, and temperature extremes is crucial.

The following table compares a standard industrial-grade Precious Metal Brush Motor from Ruixing against a conventional carbon brush model:

| Parameter | Conventional Carbon Brush Motor | Ruixing Precious Metal Brush Motor |

|---|---|---|

| Typical Lifespan | 300 - 500 hours | 1,000 - 2,000 hours |

| Starting Voltage | 0.7 - 1.2 V | 0.15 - 0.3 V |

| Voltage Drop | 0.8 - 1.5 V | 0.1 - 0.3 V |

| Noise Level | 45 - 55 dB | < 35 dB |

Precious Metal Brush Motor FAQ

How does operating load affect the motor's lifespan

Consistently operating a Precious Metal Brush Motor above its rated load by even 10% can reduce its lifespan by up to 30%. For maximum longevity, ensure the motor is used within its specified torque and power ratings, a design principle Ruixing rigorously tests for.

Can this motor withstand high-vibration industrial environments

Yes, the robust construction of the Ruixing Precious Metal Brush Motor, including a balanced armature and secure brush spring tension, is specifically engineered to maintain performance and brush contact integrity in high-vibration settings, unlike many standard motors.

What maintenance is required to achieve the maximum lifespan

While these motors are largely maintenance-free, ensuring a clean operating environment free from conductive dust and periodically checking for brush wear after extensive use will help you achieve the full potential lifespan of the unit.

The data clearly shows that a Ruixing Precious Metal Brush Motor is a superior investment for minimizing downtime and reducing total cost of ownership. Do not let motor failure dictate your maintenance calendar.

Contact us today to request a custom lifespan analysis for your specific application. Our engineering team is ready to provide you with detailed specifications and samples to prove the Ruixing advantage.