Plastic Connector Mold for Communication: Precision Engineering for Advanced Connectivity

2025-08-04

In today's hyper-connected world, communication devices must operate with unmatched reliability, speed, and efficiency. Behind this performance lies a silent yet crucial component — the Plastic Connector Mold for Communication. Whether it's smartphones, routers, data hubs, or IoT devices, the structural integrity and signal transmission reliability heavily rely on high-precision molded connectors.

At Dongguan Xuan Pin Mould Technology Co., we specialize in manufacturing Plastic Connector Molds for Communication with outstanding dimensional accuracy, consistent cavity replication, and superior thermoplastic compatibility.

Why Plastic Connector Mold for Communication Is Critical

Plastic connector molds are used to produce the plastic housing and connector components that enable electrical and data signals to pass smoothly between devices. These components must withstand:

-

High signal transmission speeds

-

Thermal variation and mechanical stress

-

Compact and miniaturized device designs

-

Industry standards for conductivity and insulation

Our plastic molds are engineered to meet these strict demands while maintaining cost-effectiveness and production efficiency.

Product Overview

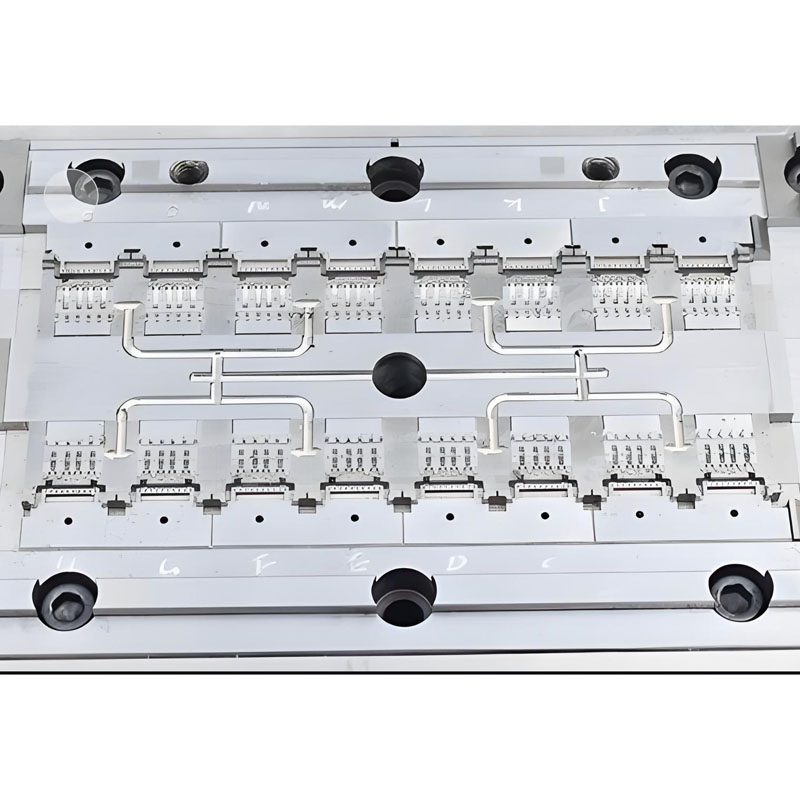

Our Plastic Connector Mold for Communication is developed using advanced CAD/CAM software, multi-cavity tooling systems, and high-grade mold steels like H13 and S136. All products go through dimensional checks, thermal resistance tests, and flow analysis simulations.

Key Specifications

| Specification | Detail |

|---|---|

| Mold Material | S136, H13, NAK80, P20, 420SS |

| Mold Base | LKM Standard, HASCO, DME |

| Cavity Number | 1~32 cavities depending on part size and production needs |

| Mold Life | ≥ 1,000,000 shots |

| Tolerance Range | ±0.01mm |

| Surface Finish | SPI A1-A3, EDM, Sandblast, Texture |

| Plastic Material Supported | PBT, PA66+GF, PPS, LCP, PC, ABS |

| Injection System | Hot Runner or Cold Runner (as per design requirement) |

| Ejection System | Ejector pins, stripper plate, lifters |

| Lead Time | 25~45 days |

| Certification | ISO 9001:2015, RoHS, SGS compliant |

Key Features

✅ High Precision Tolerances

✅ Multi-Cavity Efficiency

✅ Complex Geometry Capability

✅ Low Shrinkage & Warping Design

✅ Custom Mold Solutions

Ensures fit and function in compact communication modules.

Supports mass production with uniform quality across all units.

Accommodates intricate connector shapes, pins, and housing structures.

Optimized gating and flow paths reduce deformation.

Tailored to client-specific CAD designs and mechanical integration.

Use Cases of Plastic Connector Mold for Communication

-

5G Base Stations: High-frequency signal connectors.

-

Smartphones & Tablets: Board-to-board and wire-to-board interfaces.

-

IoT Devices: Miniaturized plastic casings for embedded communication chips.

-

Fiber Optic Modules: Precision housings for data transmission heads.

-

Automotive Telematics Units: Durable housing for network modules.

Benefits for OEMs and Communication Brands

-

Improved Product Lifespan: Molded parts resist wear, vibration, and signal loss.

-

Lower Production Cost: Reusable molds yield high-volume outputs.

-

Faster Time-to-Market: With rapid tooling and prototyping.

-

Better Signal Integrity: Consistent geometry ensures proper pin alignment and shielding.

Our Manufacturing Process Flow

-

Client Requirement Analysis

-

3D Mold Design using UG/NX or AutoCAD

-

Mold Flow Analysis using Moldex3D

-

Precision CNC Machining and EDM

-

Assembly, Fitting & Polishing

-

T1 Sampling and Part Approval

-

Final Delivery and After-Sales Support

Our Mold Gallery

| Mold Type | Image Reference | Application Area |

|---|---|---|

| USB Connector Mold | [Available on request] | Consumer Electronics |

| RJ45 Connector Mold | [Available on request] | Networking Devices |

| Micro SIM Tray Mold | [Available on request] | Mobile Communication |

| Fiber Plug Mold | [Available on request] | Fiber Optic Systems |

Frequently Asked Questions (FAQ)

Q1: What makes your Plastic Connector Mold for Communication different from others in the market?

A1: We focus on micro-tolerance accuracy (±0.01mm), multi-cavity balance, and advanced runner systems. Our team uses high-end simulation tools to ensure optimum flow, minimal warpage, and consistent part ejection. Every mold is tested with high-speed injection machines under real-world conditions.

Q2: Can your Plastic Connector Mold for Communication support high-temperature or flame-retardant plastics?

A2: Yes. Our molds are engineered to accommodate materials such as PPS, LCP, and PA66+GF, which can endure high temperatures and meet UL94 V-0 flame retardancy. Special mold coatings and hardening treatments further ensure durability under thermal cycles.

Q3: What is the typical lead time for a new Plastic Connector Mold for Communication?

A3: Generally, the lead time ranges from 25 to 45 working days depending on the complexity, number of cavities, and modification cycles. Rapid prototypes can be delivered within 10–15 days. We also offer mold validation reports and CPK studies for mass production readiness.

Why Choose Dongguan Xuan Pin Mould Technology Co.?

With over a decade of specialized experience in connector mold manufacturing, we offer unmatched technical capability and attention to detail. From mold design to mass production, we maintain full in-house control and implement rigorous QA measures.

We Provide:

-

Free DFM and Mold Flow Reports

-

Post-shipment Technical Assistance

-

Full NDA Protection for Custom Designs

-

Real-time Project Updates with Weekly Reports

Let's Build Together

The future of communication lies in devices that are faster, smaller, and more reliable. Investing in a Plastic Connector Mold for Communication from a trusted manufacturer ensures your products meet market demands with confidence. Get in touch with Dongguan Xuan Pin Mould Technology Co. for a free consultation, and let's create the future of connectivity together. Contact us today to request a quote or submit your CAD files.