How Linear Shafts Improve Precision and Efficiency in Machinery

2025-11-13

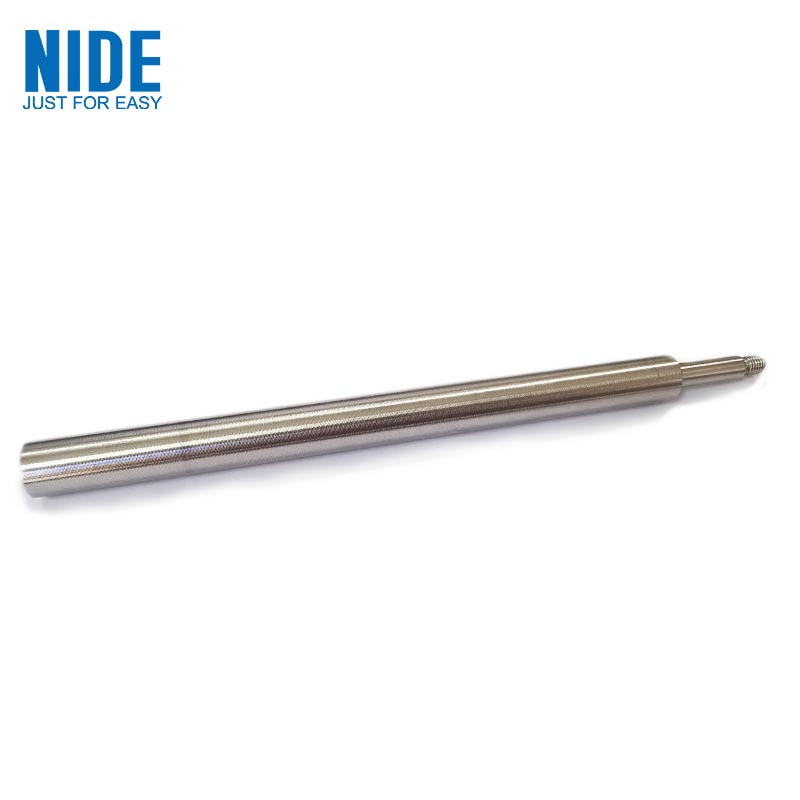

As someone who has been deeply involved in mechanical component manufacturing for years, I’ve seen how small details can make a huge difference in machine performance. At NIDE, we’ve dedicated ourselves to producing high-quality Linear Shafts that help our clients enhance both the precision and efficiency of their equipment. Whether you’re designing automation systems, CNC machinery, or robotics, the reliability of your motion components directly determines your productivity and accuracy.

Why Are Linear Shafts So Important for Modern Machinery

Linear shafts serve as the guiding foundation for motion systems. They support linear bearings, reduce friction, and ensure smooth movement of machine parts. Without a high-precision shaft, even the best machinery can suffer from vibration, wear, and performance instability.

Our customers often tell us that upgrading to a precision-ground linear shaft immediately improves product consistency and reduces downtime. This isn’t magic — it’s the result of tight dimensional control, superior materials, and careful surface treatment.

What Makes NIDE Linear Shafts Stand Out in Quality and Performance

At NIDE, every shaft goes through strict production and inspection processes. We use advanced grinding, hard chrome plating, and precision straightening technologies to ensure each piece meets demanding industrial standards. Here’s what defines our product quality:

Key Product Features

-

Material Options: GCr15, SUS304, SUS440C, C45, and custom alloys

-

Surface Hardness: HRC 58–62 for wear resistance

-

Surface Roughness: Ra ≤ 0.2 μm for ultra-smooth operation

-

Hard Chrome Thickness: 20–25 μm

-

Straightness Tolerance: ≤ 0.01 mm/m

-

Diameter Range: 3 mm to 100 mm

-

Length: Up to 6000 mm (customizable)

Product Specification Table

| Parameter | Specification Range | Description |

|---|---|---|

| Material | GCr15 / SUS304 / C45 | High-strength steel for different applications |

| Hardness | HRC 58–62 | Ensures long service life under heavy load |

| Roughness | Ra ≤ 0.2 μm | Provides smooth sliding and low friction |

| Chrome Layer | 20–25 μm | Corrosion resistance and stability |

| Straightness | ≤ 0.01 mm/m | Guarantees motion accuracy |

| Diameter | 3–100 mm | Flexible for multiple industrial systems |

| Length | Up to 6000 mm | Custom sizes available on request |

How Do Precision Linear Shafts Enhance Efficiency and Reduce Maintenance

Precision-ground linear shafts help improve mechanical motion by maintaining constant linear paths. This directly leads to:

-

Reduced Friction: Less energy loss and smoother performance.

-

Improved Accuracy: Ensures alignment and eliminates vibration during high-speed motion.

-

Extended Equipment Life: Prevents premature bearing wear and misalignment issues.

-

Lower Maintenance Costs: Stable structure means fewer replacements and adjustments.

In industries like robotics, packaging, printing, and CNC machining, this level of precision can save hours of downtime and thousands in repair costs each year.

How Can You Choose the Right Linear Shaft for Your Application

Selecting the correct shaft depends on factors like load capacity, operating speed, environment, and mounting design. We always advise clients to discuss their system conditions with our engineering team — whether you need anti-corrosion stainless steel shafts for food machinery or hardened chrome shafts for industrial automation, we can help customize the perfect solution.

What Support Can You Expect from NIDE

Beyond manufacturing, NIDE provides technical consultation, drawing assistance, and after-sales support. We focus on long-term cooperation, ensuring our clients get not just a product, but a complete motion solution tailored to their production needs.

Ready to Upgrade Your Machinery Efficiency

If you’re looking to enhance the precision and performance of your equipment with durable, high-accuracy Linear Shafts, our team at NIDE is ready to assist. Contact us today to get a professional quote or discuss your custom requirements — we’re here to help you achieve higher efficiency and better results.

👉 Contact us now to learn more or send your inquiry directly through our website.