How Can a Hollow Cup Brushless DC Motor Reduce Weight in Your Drone or Robotic Application

2025-12-03

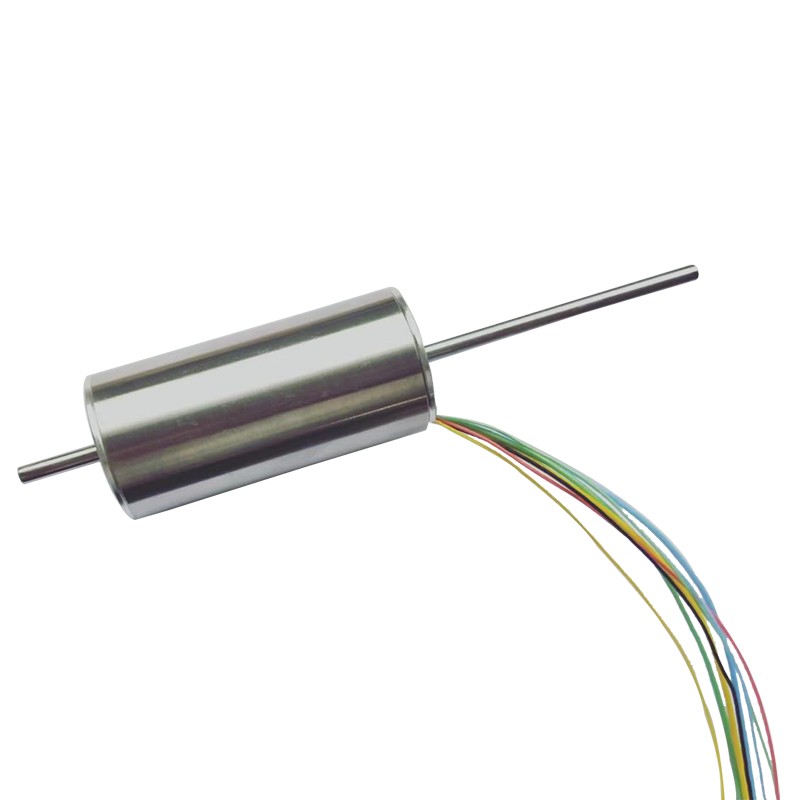

When designing drones or robotic systems, every gram matters. Reducing weight directly translates to longer flight times, greater agility, and improved overall efficiency. This is where the innovative design of the Hollow Cup DC Brushless Motor from RuiXing provides a decisive advantage. By fundamentally re-engineering the core component—the rotor—RuiXing motors deliver exceptional power without the burden of unnecessary mass.

The secret lies in the unique "hollow cup" or coreless rotor design. Unlike traditional motors that use an iron core wound with copper wire, our rotor is a self-supporting, lightweight cylinder of windings. This eliminates the heavy iron core, which is a primary source of weight, inertia, and energy loss in conventional motors. The benefits for your application are immediate and significant:

-

Drastic Weight Reduction: The absence of the iron core can reduce motor weight by 30% to 50% compared to similarly powered standard motors.

-

Higher Power-to-Weight Ratio: You get more torque and power output for a given weight, enabling faster acceleration and more responsive control.

-

Improved Dynamic Response: With minimal rotor inertia, the motor starts, stops, and changes speed almost instantaneously, enhancing precision in robotic arms or drone stabilization gimbals.

-

Greater Energy Efficiency: Eliminating iron-core losses (like eddy currents) means more electrical energy is converted into motion, not wasted as heat, thereby extending battery life.

RuiXing Hollow Cup Brushless DC Motor - Key Specifications

| Parameter | Model RX-HC-4205 | Model RX-HC-2203 | Benefit for Your Design |

|---|---|---|---|

| Stall Torque | 0.25 Nm | 0.08 Nm | Provides strong rotational force for reliable movement. |

| No-Load Speed | 15,000 RPM | 22,000 RPM | Enables high-speed operation for propellers or fast maneuvers. |

| Motor Weight | 42g | 18g | Critical for weight-sensitive applications. |

| Continuous Current | 3.5A | 1.2A | Supports sustained operation under load. |

| Peak Efficiency | >92% | >90% | Maximizes battery runtime and minimizes heat generation. |

Hollow Cup DC Brushless Motor FAQ

What are the main maintenance concerns for a hollow cup motor?

The brushless design inherently requires less maintenance than brushed motors. The primary consideration is bearing care. Ensuring the motor is protected from excessive dust, moisture, and physical impact will maximize its long operational life, which is a hallmark of RuiXing motor construction.

Can these motors handle high-vibration environments like drones?

Absolutely. The coreless rotor is not only lightweight but also exceptionally robust due to its bonded winding structure. This design allows RuiXing Hollow Cup DC Brushless Motors to withstand the constant vibrations experienced in drone flight and robotic motion better than motors with delicate iron laminations.

How does the efficiency gain translate to real-world drone performance?

Higher efficiency means less wasted energy as heat and more power directed to the propeller. For a drone, this directly results in extended flight time per battery charge and more stable performance, as the power system runs cooler and more reliably—a key advantage when using RuiXing motors in your aerial platform.

Ready to elevate your design with unparalleled power density and efficiency? Contact us today to discuss your specific requirements. Our engineering team at RuiXing is ready to help you select the perfect lightweight Hollow Cup DC Brushless Motor to bring your most innovative drone and robotic applications to life.